1. Understanding the Procurement Journey 🔍

The lantern sourcing process for B2B buyers involves more than simply requesting prices. It begins with defining the right specification: material, finish, IP rating, lighting type, and intended market. Importers that approach the Request for Quotation (RFQ) phase with a detailed brief often save weeks of unnecessary clarification and avoid costly mismatches during mass production.

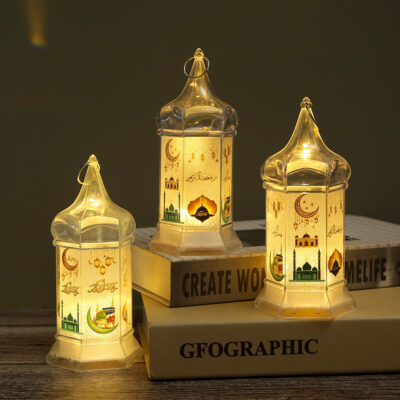

Before sending your first RFQ, decide your product category—whether decorative, LED, solar, or wooden lanterns—and confirm which segment aligns with your retail or wholesale strategy. Many successful buyers use benchmark data from Lantern Wholesale to understand MOQ tiers, seasonal demand, and container optimization strategies before proceeding.

2. RFQ Stage: Defining What You Need 📋

A good RFQ covers not just dimensions or materials but also performance expectations and testing standards. For instance:

-

Material & Finish: Brass, aluminum, or wood—each offers a different look and weather resistance.

-

Function: Is it decorative, functional, or solar-powered?

-

Certification: CE, RoHS, or ISO compliance required for your target market.

When working with a qualified Lantern Factory, it’s important to request sample lead times, cost breakdowns, and packaging details upfront. This transparency helps both parties set clear expectations on cost per unit and shipment readiness.

3. Sampling and Prototype Development 🧩

Samples should validate not only visual appeal but also mechanical strength, electrical safety, and finish consistency. For LED models, verify driver stability and luminous flux over time. For decorative lines, focus on color uniformity, surface polish, and glass fit.

You can request:

-

Pre-production samples for visual approval

-

Engineering samples to test assembly tolerance

-

Pilot samples from the actual production line

A robust sampling cycle typically takes two to three rounds before final approval, especially for OEM or custom designs.

4. Production Oversight and Quality Assurance 🏭

Once production starts, the key to maintaining consistency is structured quality control. Buyers often adopt the AQL (Acceptable Quality Level) system with checkpoints at three stages:

-

Initial Production Check (IPC) – To verify materials and components.

-

During Production Inspection (DUPRO) – To ensure adherence to specifications.

-

Final Random Inspection (FRI) – To assess packaging, labeling, and product safety before shipment.

Photographic records and batch samples should be archived for traceability. Some importers also run third-party inspections when order volumes exceed one container.

5. Packaging, Labeling & Logistics 📦

Durable packaging protects lanterns from breakage during sea or air freight. Corrugated cartons with EPE or foam inserts are standard, and each master carton should contain an external label showing SKU, PO number, and weight. Discuss packaging standards early—reducing damage rate from 2% to below 0.5% can save significant costs in returns and replacements.

When consolidating shipments, ensure your supplier provides volumetric data (CBM) for efficient container utilization. FCL (Full Container Load) often yields better cost efficiency compared to LCL (Less-than-Container Load).

6. Compliance, Documentation & After-Sales 📑

A professional supplier should provide a complete documentation set including:

-

Commercial Invoice & Packing List

-

Certificate of Origin

-

Test Reports or Compliance Certificates

-

Warranty or After-Sales Terms

For solar or LED lanterns, ensure that all battery and lighting components comply with transportation regulations such as UN38.3 and IEC 62133.

7. Building Long-Term Supplier Relationships 🤝

B2B success is not just about finding the lowest cost—it’s about finding partners who understand your brand’s value proposition. Maintain open communication, track delivery performance, and share quarterly forecasts to secure priority production slots during peak seasons.

Reliable cooperation with an experienced lantern manufacturer will help you maintain quality consistency and brand reputation over multiple product cycles.

8. Final Thoughts 🌏

Global lantern procurement requires a mix of technical insight, supply chain management, and quality control discipline. From defining your RFQ to approving your final shipment, a structured workflow minimizes surprises and builds long-term profitability. With well-chosen partners, you can focus less on firefighting and more on scaling your distribution network.